1.Ukukhethwa kwe-thyristor ochungechungeni kanye nesekethe ye-resonant ehambisanayo

Uma ama-thyristors esetshenziswa ochungechungeni kanye nesekethe ye-resonant ehambisanayo, ukushaya kwe-trigger yesango kufanele kube namandla, okwamanje kanye ne-voltage kufanele kube ibhalansi, futhi izici zokuqhutshwa nokutholwa kwamadivayisi kufanele zikhethwe ngokusebenza okufanayo.Ikakhulukazi uma amadivayisi asebenza ngesekhethi ephezulu ye-di/dt ye-inverter ochungechungeni, izici zokuhlehla zokuhlehla zidlala indima enkulu ekulinganiseni amandla kagesi aguqukayo.

2.Ukuhlanganiswa kokushisa kokushisa kanye nedivayisi

Imodi yokupholisa yama-assemblies ihlanganisa ukupholisa kwemvelo nge-heat sink, ukupholisa umoya okuphoqelekile kanye nokupholisa amanzi.Ukuze unike amandla idivayisi ukuthi isebenzise ukusebenza okulinganiselwe ngokuthembekile kuhlelo lokusebenza, kuyadingeka ukukhetha efanelekileamanzi okupholisa heatsinkfuthi uyihlanganise ngedivayisi ngendlela efanele.Okufana nokuqinisekisa ukumelana nokushisa kwama-Rj-hs phakathi kukasinki wokushisa kanye ne-thyristor/diode chip ihlangabezana nemfuneko yokupholisa.Izilinganiso kufanele zibhekwe njengokulandelayo:

2.1Indawo yokuxhumana ye-heater sink kufanele ifane nosayizi wedivayisi ukuze kugwenywe ukulimala okuyisicaba noma okugwegwile kwedivayisi.

2.2Isicaba kanye nokuhlanzeka kwendawo othintana nayo usinki wokushisa kufanele kuqedwe kakhulu.Kutuswa ukuthi ubulukhuni obungaphezulu besinki wokushisa bube buncane noma bulingane no-1.6μm, futhi ukucaba kungaphansi noma kulingana no-30μm.Ngesikhathi sokuhlanganiswa, indawo yokuxhumana yedivayisi kanye nosinki wokushisa kufanele ihlale ihlanzekile futhi ingenawo uwoyela noma okunye ukungcola.

2.3Qinisekisa ukuthi indawo yokuxhumana yedivayisi nosinki wokushisa ngokuyisisekelo kuyahambisana futhi kugxile.Ngesikhathi somhlangano, kuyadingeka ukusebenzisa ukucindezela ngokusebenzisa i-centerline yengxenye ukuze amandla okucindezela asakazwe ngokulinganayo phezu kwayo yonke indawo yokuxhumana.Ekuhlanganiseni ngesandla, kunconywa ukusebenzisa isikrufu se-torque ukuze usebenzise amandla alinganayo kuwo wonke amantongomane aqinisayo ngokushintshana, futhi ingcindezi kufanele ihlangabezane nedatha enconyiwe.

2.4Sicela unake kakhulu ukuze uhlole ukuthi indawo othintana nayo ihlanzekile futhi iyisicaba uma uphinda usebenzisa usinki wokushisa opholisa amanzi.Qiniseka ukuthi asikho isikali noma ukuvaleka emgodini webhokisi lamanzi, futhi ikakhulukazi akukho ukuntenga endaweni yokuxhumana.

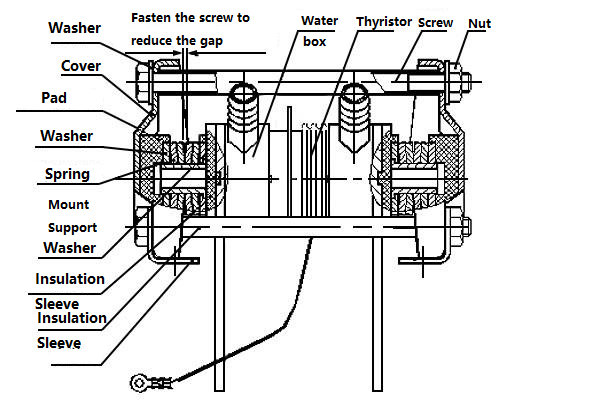

2.5 Umdwebo womhlangano wesinki wokushisa wokupholisa amanzi

Indaba ebaluleke kakhulu yokuqinisekisa ukusebenza okuthembekile kwesekethe ukukhetha idivayisi efanelekayo kanye nesinki sokushisa.Iamandla aphezulu capsule thyristorkanye ne-diode ekhiqizwe i-Runau Semiconductor ikhanyiswe kakhulu kuzicelo zefrikhwensi yomugqa.Amandla kagesi afakiwe asukela ku-400V kuye ku-8500V kanye nobubanzi bamanje asuka ku-100A kuye ku-8KA.Kuhle kakhulu ku-pulse ye-trigger yesango eqinile, ibhalansi enhle yokuqhuba nokululama.Isinki sokushisa sokupholisa amanzi siklanywe futhi sikhiqizwa izinsiza ze-CAD ne-CNC.Kuyasiza ukuthuthukisa ukusebenza kwamadivayisi.

Isikhathi sokuthumela: Apr-07-2022