1. Umhlangano wokupholisa amanzi we-heat sink kanye nedivayisi

Imodi yokupholisa yama-assemblies ihlanganisa ukupholisa kwemvelo nge-heat sink, ukupholisa umoya okuphoqelekile kanye nokupholisa amanzi.Ukuze unike amandla idivayisi ukuthi isebenzise ukusebenza okulinganiselwe ngokuthembekile kuhlelo lokusebenza, kuyadingeka ukukhetha efanelekileamanzi okupholisa heatsinkfuthi uyihlanganise ngedivayisi ngendlela efanele.Okufana nokuqinisekisa ukumelana nokushisa kwama-Rj-hs phakathi kukasinki wokushisa kanye ne-thyristor/diode chip ihlangabezana nemfuneko yokupholisa.Izilinganiso kufanele zibhekwe njengokulandelayo:

1.1 Indawo yokuxhumana ye-heater sink kufanele ifane nosayizi wedivayisi ukuze kugwenywe ukulimala okuyisicaba noma okugwegwile kwedivayisi.

1.2 Ukuba isicaba nokuhlanzeka kwendawo othintana nayo usinki wokushisa kufanele kuqedwe kakhulu.Kutuswa ukuthi ubulukhuni obungaphezulu besinki wokushisa bube buncane noma bulingane no-1.6μm, futhi ukucaba kungaphansi noma kulingana no-30μm.Ngesikhathi sokuhlanganiswa, indawo yokuxhumana yedivayisi kanye nosinki wokushisa kufanele ihlale ihlanzekile futhi ingenawo uwoyela noma okunye ukungcola.

1.3 Qiniseka ukuthi indawo yokuxhumana yedivayisi kanye nesinki sokushisa ngokuyisisekelo kuyahambisana futhi kugxile.Ngesikhathi somhlangano, kuyadingeka ukusebenzisa ukucindezela ngokusebenzisa i-centerline yengxenye ukuze amandla okucindezela asakazwe ngokulinganayo phezu kwayo yonke indawo yokuxhumana.Ekuhlanganiseni ngesandla, kunconywa ukusebenzisa isikrufu se-torque ukuze usebenzise amandla alinganayo kuwo wonke amantongomane aqinisayo ngokushintshana, futhi ingcindezi kufanele ihlangabezane nedatha enconyiwe.

1.4 Sicela unake kakhulu ukuze uhlole ukuthi indawo othintana nayo ihlanzekile futhi iyisicaba uma uphinda usebenzisa usinki wokushisa opholisa amanzi.Qiniseka ukuthi asikho isikali noma ukuvaleka emgodini webhokisi lamanzi, futhi ikakhulukazi akukho ukuntenga endaweni yokuxhumana.

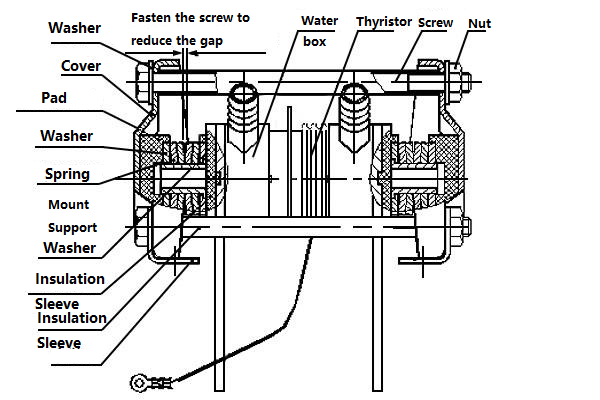

1.5 Umdwebo womhlangano wesinki wokushisa wokupholisa amanzi

2. Ukucushwa namamodeli we-heatsink

Ngokuvamile sizosebenzisa uchungechunge olupholile ngamanzi lwe-SS kanye nochungechunge olupholile umoya lwe-SF kanye nengxenye ekhethekile ye-heatsink yokwenza ngokwezifiso ukupholisa amadivayisi we-semiconductor yamandla.Sicela ubheke ithebula elingezansi ukuze uthole amamodeli we-heatsink ajwayelekile amisiwe futhi anconyiwe ngokuya ngesilinganiso esimaphakathi sesimo samanje samadivayisi.

| Ikalwe Okumaphakathi Kwesifundazwe (A) I-ITAV/IFAV | Imodeli Ye-Heatsink Enconyiwe | |

| Amanzi apholile | Kupholiswe umoya | |

| 100A-200A | I-SS11 | SF12 |

| 300A | I-SS12 | SF13 |

| 400A | SF13/SF14 | |

| 500A-600A | SS12/SS13 | SF15 |

| 800A | I-SS13 | SF16 |

| 1000A | I-SS14 | SF17 |

| 1000A/3000A | I-SS15 |

|

IUchungechunge lwe-SF heatsink epholile emoyeniikhethwa ngaphansi kwesimo sokupholisa umoya okuphoqelekile (isivinini somoya ≥ 6m/s), futhi ikhasimende kufanele likhethe ngokuvumelana nesidingo sangempela sokushabalalisa ukushisa nokuthembeka.Ngokuvamile akunconywa ukusebenzisa i-heatsink epholile emoyeni ukupholisa idivayisi ngaphezu kuka-1000A.Uma kusetshenziswa irediyetha epholile emoyeni empeleni, isilinganiso samanje socingo kufanele sehliswe ekusebenzeni.Uma zingekho izidingo ezikhethekile zohlelo lokusebenza, i-heatsink ivame ukukhethwa ngokuya ngokucushwa okujwayelekile.Uma kunesidingo esikhethekile esivela kukhasimende, sicela uxhumane nathi uzizwe ukhululekile.

3. Ukuncoma

Indaba ebaluleke kakhulu yokuqinisekisa ukusebenza okuthembekile kwesekethe ukukhetha idivayisi efanelekayo kanye nesinki sokushisa.Iamandla aphezulu thyristorfuthihigh power diodeekhiqizwa yi-Runau Semiconductor akhanyiswe kakhulu kuzicelo zefrikhwensi yomugqa.Amandla kagesi afakiwe asukela ku-400V kuye ku-8500V kanye nobubanzi bamanje asuka ku-100A kuye ku-8KA.Kuhle kakhulu ku-pulse ye-trigger yesango eqinile, ibhalansi enhle yokuqhuba nokululama.Isinki sokushisa sokupholisa amanzi siklanywe futhi sikhiqizwa izinsiza ze-CAD ne-CNC.Kuyasiza ukuthuthukisa ukusebenza kwamadivayisi.

Isikhathi sokuthumela: Apr-27-2023