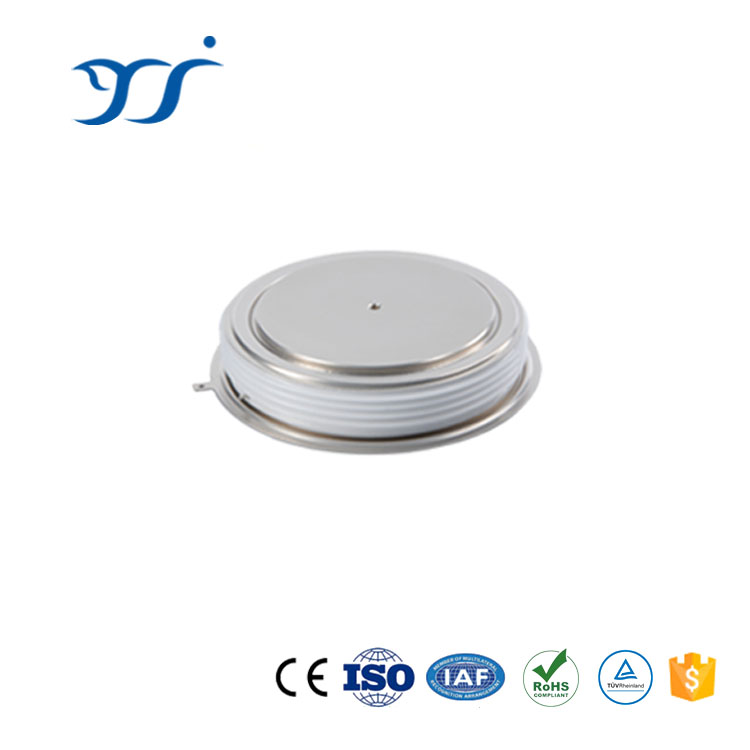

I-High Standard Fast Switch Thyristor

I-Fast Switch Thyristor (uchungechunge olusezingeni eliphezulu lwe-YC)

Incazelo

Ubuchwepheshe obujwayelekile bokukhiqiza be-GE bethulwa futhi baqashwa yi-RUNAU Electronics kusukela ngo-1980s.Isimo esiphelele sokukhiqiza nokuhlola besihambisana ngokuphelele nesidingo semakethe yase-USA.Njengengqalabutho yokukhiqiza i-thyristor e-China, i-RUNAU Electronics yayinikeze ubuciko bemishini kagesi yezwe e-USA, emazweni aseYurophu nakubasebenzisi bomhlaba.Ifaneleka kakhulu futhi ihlolwe amakhasimende futhi ukuwina okukhulu nenani kwadalelwa ozakwethu.

Isingeniso:

1. I-chip

I-thyristor chip ekhiqizwa yi-RUNAU Electronics isetshenziswa ubuchwepheshe bokusebenzisa i-sintered alloying.I-silicon ne-molybdenum wafer yashiswa ukuze ihlanganiswe nge-aluminium ehlanzekile (99.999%) ngaphansi kwe-vacuum ephezulu kanye nendawo yokushisa ephezulu.Ukuphathwa kwezimpawu ze-sintering kuyisici esibalulekile sokuthinta ikhwalithi ye-thyristor.Ulwazi lwe-RUNAU Electronics ngaphezu kokuphatha ukujula kwe-alloy junction, flatness surface, i-alloy cavity kanye nekhono eligcwele lokusabalalisa, iphethini yendilinga, isakhiwo sesango esikhethekile.Futhi ukucubungula okukhethekile kwasetshenziswa ukuze kuncishiswe impilo yenkampani yenethiwekhi yedivayisi, ukuze isivinini sokuhlanganiswa kabusha kwenkampani yenethiwekhi sisheshiswe kakhulu, inkokhiso yokuhlehla yokutakula yedivayisi iyancipha, futhi isivinini sokushintsha siyathuthukiswa ngenxa yalokho.Izilinganiso ezinjalo zasetshenziswa ukuze kuthuthukiswe izici zokushintsha ngokushesha, izici zesifunda, kanye nempahla yamanje yokwanda.Ukusebenza kanye nokusebenza kwe-thyristor kuthembekile futhi kusebenza kahle.

2. Encapsulation

Ngokulawula ngokuqinile ukucaba nokuhambisana kwe-molybdenum wafer kanye nephakheji yangaphandle, i-chip ne-molybdenum wafer izohlanganiswa nephakheji yangaphandle ngokuqinile futhi ngokuphelele.Okunjalo kuzothuthukisa ukumelana kwe-surge current kanye ne-high short circuit current.Futhi ukukalwa kobuchwepheshe bokuhwamuka kwe-electron kwasetshenziswa ukuze kwakhiwe ifilimu ye-aluminium ewugqinsi endaweni eyisicwecwana se-silicon, futhi ungqimba lwe-ruthenium olubekwe phezu kwe-molybdenum luzothuthukisa ukumelana nokukhathala okushisayo, isikhathi sokuphila komsebenzi sokushintshwa kwe-thyristor esisheshayo sizokwenyuka kakhulu.

Ukucaciswa kobuchwepheshe

- Shintsha ngokushesha i-thyristor enohlobo lwe-alloy chip ekhiqizwe yi-RUNAU Electronics ekwazi ukuhlinzeka ngemikhiqizo efaneleke ngokugcwele yezinga lase-USA.

- IGT, VGTnamiHamanani okuhlola aku-25℃, ngaphandle uma kushiwo ngenye indlela, wonke amanye amapharamitha amanani okuhlola ngaphansi kuka-T.jm;

- I2t=ngi2F SM×tw/2,tw= Ububanzi besisekelo segagasi le-Sinusoidal uhhafu wamanje.Ku-50Hz, I2t=0.005I2I-FSM(A2S);

- ngo 60Hz:II-FSM(8.3ms)=II-FSM(10ms)×1.066,Tj=Tj;I2t(8.3ms)=I2t(10ms)×0.943,Tj=Tjm

Ipharamitha:

| UHLOBO | IT(AV) A | TC ℃ | VI-DRM/VI-RRM V | II-TSM @TI-VJIM&10ms A | I2t A2s | VTM @IT&TJ=25℃ V / A | tq μs | Tjm ℃ | Rjc ℃/W | Rcs ℃/W | F KN | m Kg | IKHODI | |

| Amandla kagesi afinyelela ku-1600 V | ||||||||||||||

| YC476 | 380 | 55 | 1200 ~ 1600 | 5320 | 1.4x105 | 2.90 | 1500 | 30 | 125 | 0.054 | 0.010 | 10 | 0.08 | T2A |

| YC448 | 700 | 55 | 1200 ~ 1600 | 8400 | 3.5x105 | 2.90 | 2000 | 35 | 125 | 0.039 | 0.008 | 15 | 0.26 | I-T5C |

| Amandla kagesi afinyelela ku-2000 V | ||||||||||||||

| YC712 | 1000 | 55 | 1600 ~ 2000 | 14000 | 9.8x105 | 2.20 | 3000 | 55 | 125 | 0.022 | 0.005 | 25 | 0.46 | I-T8C |

| YC770 | 2619 | 55 | 1600 ~ 2000 | 31400 | 4.9x106 | 1.55 | 2000 | 70 | 125 | 0.011 | 0.003 | 35 | 1.5 | I-T13D |